When converting brings colorful blessings

COLOR is a wonderful play of light on pigments. The pigments that absorb the particular wavelength of light appear as we see them. If a pigment is blue it will absorb that particular blue in white light and our eyes perceive it as that color. That happens when expressed on monitor and when printed on paper.

In trying to replicate those colors on a screen or monitor, the color model of Red-Green-Blue (RGB) was created. These three colors are not all primaries, green being a product of yellow and blue. In the process of converting light into a screen, RGB is the best. With equal amounts of these colors, white is created as it cancels out each other. Monitors all use RGB because it has a wider spectrum.

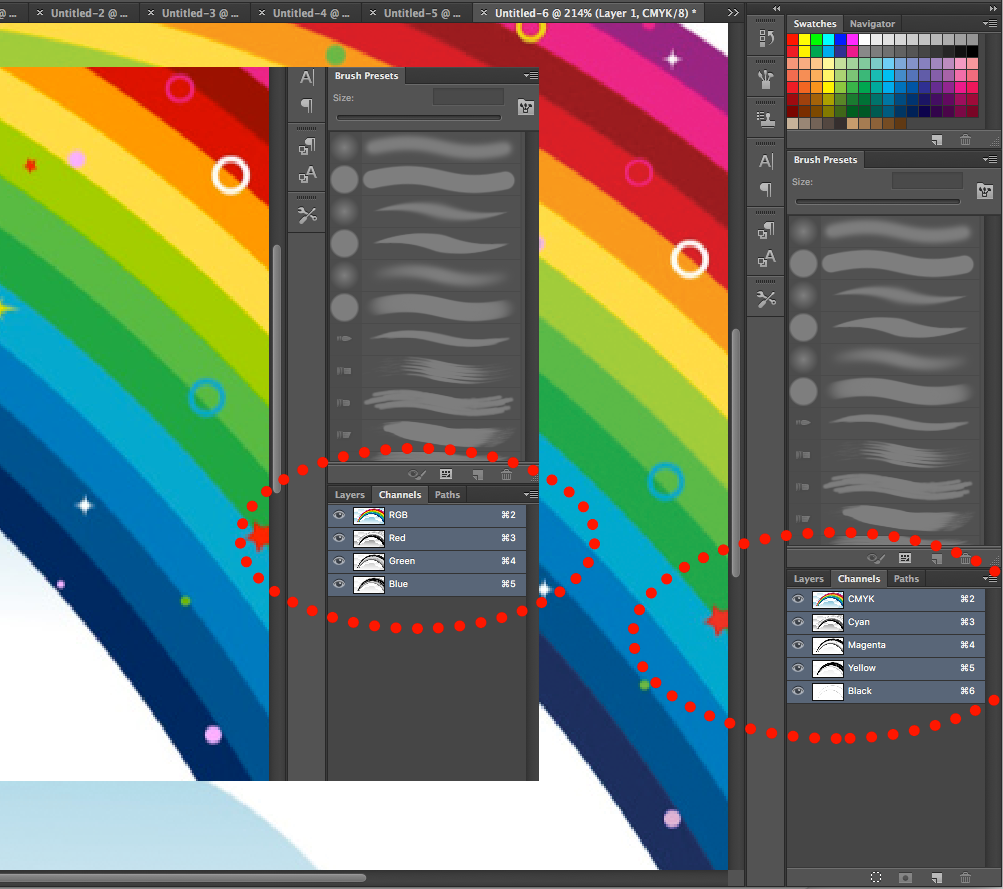

However, when we bring your projects from screen to print, it is essential that you convert your work from RGB to CYMK. The simple reason is this. We print in CMYK. Our color presses, whether they are traditional offset or digital offset presses, print in the CMYK standard. To see what we mean, check out our printing process.

If RGB has a wide spectrum of light, CMYK does not. In fact, the CMYK color space can be so very specific, each gradient of color has a precise space that is so precise. This is why when you use a Pantone color guide, the mix of colors, in a formula can be done so that colors can come out precisely the same each time.

Notice how, in the CMYK color space, it is a percentage of color that is used. In the color pickers of Adobe Photoshop for example, there are specific Pantone numbers for specific mixes of CMYK. This CMYK color space 100% black is a solid color but 80% black, 20% yellow creates a colder black where as adding red gives it an elegant feel.

So to achieve an excellent match of color from project to printer it is necessary to convert from RGB to CMYK. On image editing or vector graphic software such as Adobe Photoshop or Illustrator, or Corel Draw, preparing art files for final offset or digital printing, will be processed in the RGB color space. This space has a conversion protocol to the CMYK color space. This means your dark blue in RGB becomes perhaps 60% black and 100% blue so achieve a dark naval blue tone. Or the orange on the RGB color space become 70% magenta, 60% yellow and 20% black. Without conversion, the digital offset printer or the computerized plate maker will not know how to pitch the dots of moderate the ink.

When we start work on a project on a monitor the color image information we use is in RGB format until the end of the project. The advantages include having smaller files because projects are using color in three channels rather than four. Color balance is easier to achieve in the RGB color space. But once projects are finished you lock it in and convert CMYK format.

When you convert an RGB image to a CMYK image, the colors may change slightly. This may or may not happen, depending on the colors involved. But rest assured on CMYK the colors are more accurate for printing. Digital offset printing is best suited to the RGB to CMYK conversion process.

Of course, before you convert from RGB to CMYK, you must make all corrections to your images, vectors and photos within the RGB color space. Then, convert the images to CMYK prior to placing the TIFF files in your page composition software, CorelDraw or InDesign. By color correcting the image in RGB you can, fix any flaws, remove any dust and so on with the full spectrum of available color. Then when you convert from RGB mode to CMYK you must then review the image on-screen in CMYK mode.